Wine Cellar Dynamics and Construction Guide

Stratification

How a Cellar Warms Up and Cools Down

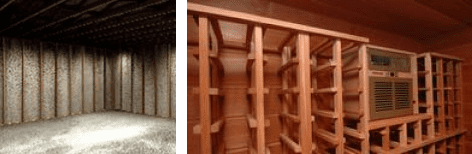

Most people never think about how a room warms up or cools down, but again it is more complex than most realize. Warmer air rises, and cooler air sinks. Old southern homes were built with tall ceilings, where the warmest air would rise up above the people. Old homes in the north were built with lower ceilings to keep the warm air at people’s level. Both are based on the fact that a room warms from the topmost people down and cools from the bottom up. It changes temperature by way of stratification. The top of the room will always be warmer than the bottom. So, how does this happen? Most heat enters the cellar through the various surfaces (floor, ceiling, walls, door, etc.) Molecules of air that are in contact with a surface are warmed up, become lighter than the surrounding molecules, and rise to the top of the cellar. These warmer molecules all gather at the top of the cellar, making a warm layer against the ceiling. As more and more molecules are warmed and raise upward, this warm layer grows down the room. Meanwhile, the lower portion of the cellar, under the warm layer, remains at a very stable colder temperature. A thin "stratification" layer that moves down the room when the cooling unit is off and up when the unit is cooling separates the upper warm air layer and the lower cold air. The Breezaire cooling unit has its temperature sensor located behind the return air grille.

If the unit is mounted near the ceiling, the growing warm air layer will be sensed, and the unit will turn on before the warm air gets to the bottom of the unit. Air from the warm layer is pulled into the unit, cooled, and blown out across the ceiling. The air below the level of the unit is not disturbed and will remain at a very constant temperature. All Breezaire cooling systems are specialized designs that create the kind of carefully controlled environment demanded by products that are highly sensitive to changes in temperature and humidity. They are not intended for use in standard refrigeration applications. For assistance in specifying the best system for your unique requirements and in creating the ideal storage environment, contact your authorized Breezaire dealer.

Relative Humidity

Simple Illustration of Relative Humidity Phenomena

This is a fairly complex subject and is based on the study of psychometrics. While the word may be fun to say, the topic is a real headache. In short, relative humidity is calculated from a fraction, where the numerator is the amount of moisture in the air, and the denominator is the maximum amount of moisture the air is capable of holding at its current temperature. This fraction is divided and multiplied by 100 to give the answer as a percentage. For a given amount of absolute moisture in the air, the relative humidity will vary according to the temperature. The warmer the air, the lower the relative humidity. As a simple way to illustrate this phenomenon, imagine a clear, sealed box. Inside the box are a thermometer and a hygrometer (a device to measure relative humidity). When the box is sealed, the thermometer reads 75° F, and the hygrometer reads 50%. Now, place the box in a large walk-in refrigerator. (Remember that it’s sealed, no air or moisture can leave or enter the box.) As the temperature begins to drop, the relative humidity will rise. When the temperature reaches 55° F, the relative humidity will be 100%, and the box will begin to fog up as moisture condenses on the walls.

This is because colder air cannot hold as much moisture as warm air; therefore, the bottom of the fraction has become smaller, and the percent relative humidity goes up. If the box is removed from the refrigerator and allowed to return to 75° F, the moisture will re-evaporate, and the relative humidity will return to 50%. Air conditioners and refrigeration units are designed to chill the air to a very low temperature as it passes through the unit. This removes as much moisture as possible for the comfort of people or the prevention of ice formation. If these systems were used in a well-sealed enclosure, the relative humidity would be reduced to an extremely low level, which is very bad for wine.

Breezaire cooling units are designed to chill the air only enough to remove the excess moisture, leaving enough moisture to keep the wine healthy. In the wine cellar, desired conditions are generally around 55° F and 50% to 75% relative humidity. If the cellar is closed and the cooling unit is originally turned on when conditions are at 75° F and 50% relative humidity, it will be necessary to not only cool the cellar but to remove some moisture. If moisture were not removed, the relative humidity would reach 100%, mold and mildew would form on the bottles and walls, and labels would fall off. Additionally, if warm moist air infiltrates the cellar, the excess moisture must be removed, or the relative humidity will rise to unacceptable levels. The cooling unit will be overworked, and the excess water could overflow from the unit, making a mess. All Breezaire cooling systems are specialized designs that create the kind of carefully controlled environment demanded by products that are highly sensitive to changes in temperature and humidity. They are not intended for use in standard refrigeration applications. For assistance in specifying the best system for your unique requirements and in creating the ideal storage environment, contact your authorized Breezaire dealer.

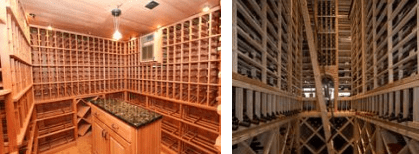

Enclosure Requirements

To use the Sizing Guide below, the enclosure to be cooled must be built to the following minimum specifications. If the enclosure cannot be built to these minimum specifications, consult your Breezaire dealer for assistance in choosing the correct unit.

All walls, floors, and ceilings should have a vapor barrier. This vapor barrier should be installed on the warm side of the insulation. All interior walls and floors should be lined with a minimum of R-11 insulation, and exterior walls and ceiling insulation value should be a minimum of R-19. There should be no glass doors and/or windows.

All joints, door frames, electrical outlets or switches, and any pipes or vents which go through the enclosure should be sealed to prevent air and moisture leakage into the room.

Doors into the enclosure should be of minimum size, insulated to R-11, and tightly sealed with high-quality weather stripping. Be sure to seal the bottom of the door and behind the door frame's molding.

Enclosure lighting should be of low wattage, with a timer to insure lights are not left on when the enclosure is unoccupied. Recessed lighting should not be used, as they will allow outside air to enter the enclosure.

No enclosure wall should receive direct sunlight or strong wind. Concrete and brick are not insulation or moisture barriers.

Note: Glass doors and/or windows are not included in our calculations and should not be used in a wine enclosure.

Sizing Guide and Specifications

| Model | Cu.Ft. (MIN. to MAX.) |

|---|---|

| WKL 1060 | 0 to 140 cu.ft. |

| WKL/WKSL 2200 | 140 to 265 cu.ft. |

| WKL 3000 | 265 to 650 cu.ft. |

| WKL/ WKSL 4000 | 650 to 1000 cu.ft. |

| WKL 6000 | 1000 to 1500 cu.ft. |

| WKL 8000 | 1500 to 2000 cu.ft |

Enclosure volume is calculated by multiplying its length by its height by its width.

Note: Do not use this guide for WKCE units. Their configuration limits their use to cabinets or narrow spaces.